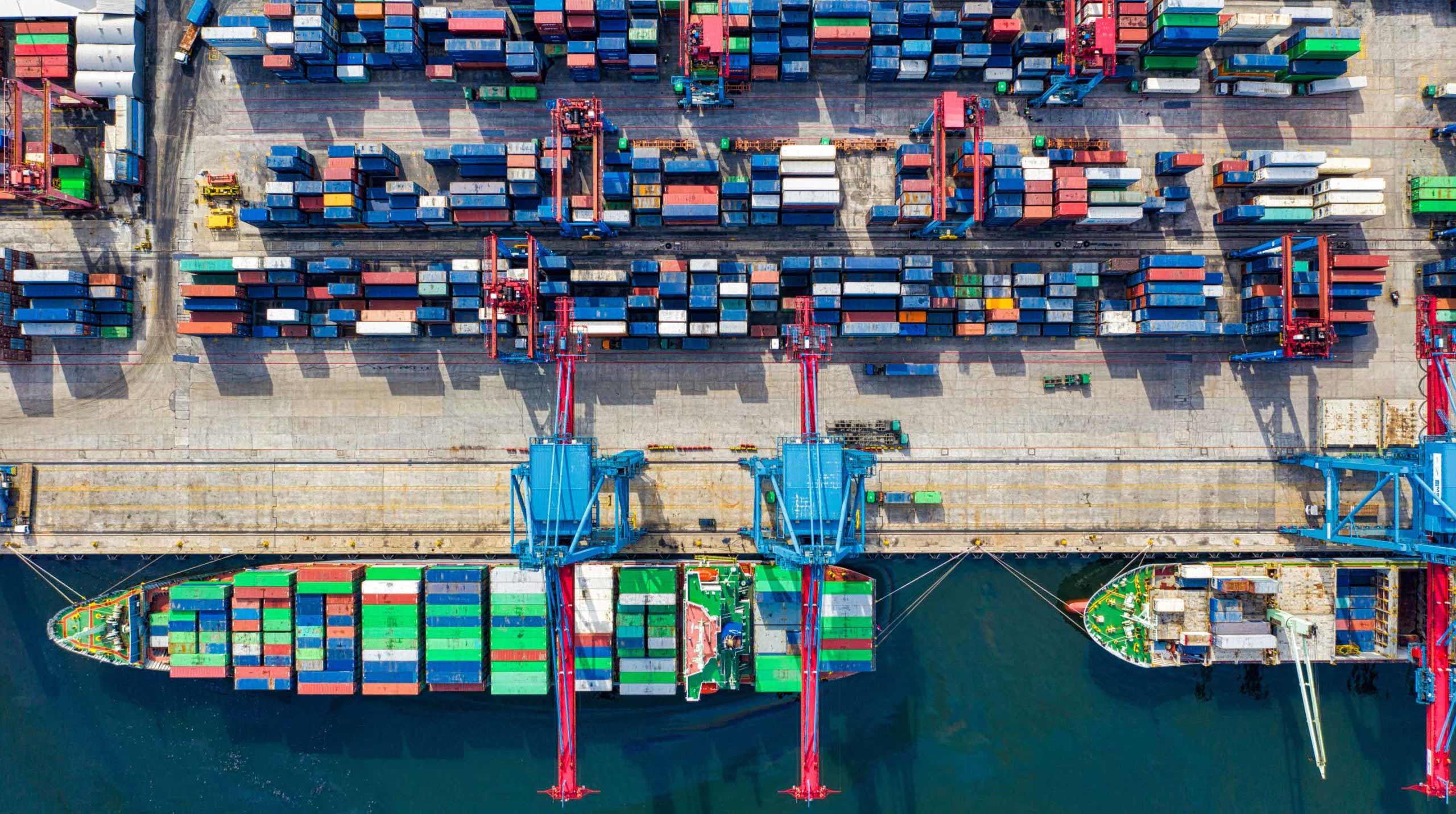

The emergence of the novel coronavirus in Spring 2020 was a very real stress test for manufacturing’s global supply chains, exposing vulnerabilities and opportunities to improve across the board.

In an effort to improve post-COVID robustness and resiliency, manufacturers of all sizes and industries are working quickly to stabilize and transform their ecosystems, rebalancing their upstream suppliers and downstream partners in the process. But several data-driven obstacles lie in their path to digital transformation and optimization.

Three data-driven obstacles slowing manufacturing’s supply chain optimization

- Data quality and consistency: All manufacturers rely on suppliers of raw materials, components, and even sub-assemblies for more complex products like aircraft and automobiles. Depending on the product being supplied, the number of attributes associated with it may range from dozens (type, weight, color, volume, size, etc.) to potentially thousands for more complex items like aerospace cockpit assemblies.

Something as seemingly simple as a cosmetic product manufactured by one Persistent customer for global retail sales has as many as 350 attributes that must be created, maintained, and shared with downstream partners. - Supplier onboarding and supplier management: With supplier ecosystems in flux, manufacturers need to be able to quickly determine which suppliers are enhancing the manufacturer’s performance and which ones are holding them back. That’s not easy when the roster of suppliers can stretch into the thousands, and the products they supply can range into the millions—particularly if the industries the manufacturer supports are heavily regulated.

In the case of one Persistent customer, a manufacturer of dairy products in Europe, the supply chain for food intended for human consumption is subject to significant oversight by the European Union.

Adding new suppliers—or switching suppliers quickly in the face of an event like a pandemic—puts the manufacturer at significant risk, particularly if failure to deliver product and data in the right manner could lead to a highly-visible quality control and recall issue for the manufacturer’s consumer brands. - Bill of Materials support: All manufactured products consist of Bills of Materials (BOMs), the list of components, parts, sub-assemblies, and raw materials that comprise the finished product, down to the nut and washer.

In an era of mass customization and just-in-time manufacturing, many product BOMs are generated dynamically based on the specific characteristics of the products being purchased. But automatically creating these BOMs requires that all of the parts data involved be complete, accurate, and consistent—qualities that are difficult to confirm when BOMs can consist of thousands of line items.

This issue isn’t limited to highly complex products either; one Persistent customer manufactures doors that sell in home improvement chains across the U.S. Simple variations in shape, design, material, color, glass type, hardware type, etc. create a catalog of more than 30,000 distinct products for doors, each with their own BOM based on what the customer selects in store.

Now imagine the consequences if the local installer finds that the door has shipped with a silver doorknob rather than the brass one specified, due to a data error in the BOM. That mistake can reflect poorly on the retailer and the manufacturer alike.

Data is the lifeblood of the digital transformation of manufacturing, which means not only must the products being supplied or manufactured be current, correct, and complete, but the data associated with those products must also meet those high standards. What’s needed is a “single source of truth” across the manufacturer’s supply chain.

IBM Product Master: the single source of truth

IBM Product Master—formerly known as IBM InfoSphere Master Data Management Collaborative Edition—has been a trusted solution for more than a decade for a variety of product-driven industries from retail and manufacturing to banking, healthcare, and government. IBM Product Master provides manufacturers with product information management (PIM) and master data management (MDM) capabilities to perform three critical functions:

- Collecting disparate types of product information from a variety of upstream providers like suppliers, raw materials producers, and distributors.

- Ensuring the information is complete, current, correct, and consistent, based on the organization’s unique business rules, data shapes, and data governance.

- Delivering this product information instantly and accurately to downstream partners in a variety of formats based on the recipient’s needs.

IBM Product Master’s gives manufacturers the “single version of the truth” needed to accelerate their digital transformation and deliver the resilient, robust and agile supply chain needed to succeed in the face of global disruption.

Delivering unique, sustainable business advantages

To deliver that competitive advantage, IBM Product Master relies on several core features:

- Flexibility: A flexible and adaptive data model ensures manufacturers can capture upstream information in any format.

- Quality: A powerful UI based rules engine makes it easy to create and maintain hundreds and thousands of data quality rules without the need of any coding or scripting knowledge.

- Compatibility: IBM Product Master is fully compatible with SAP, the world’s leading ERP system, and it integrates easily with other key enterprise applications larger manufacturers require.

- Error reduction: The built-in supplier portal allows for efficient collaboration with suppliers, eliminating the need for manual exchanges of product/part information.

- Analysis: Dashboards score suppliers on a variety of criteria like turnaround time, supplier data quality, and more.

- Scalability: One large European retailer supports more than 33 million product SKUs with more on the way.

- Speed: A manufacturer of luxury goods reduced the time to get new products onto their ecommerce sites from an average of 22 days to just minutes today.

The key to your success in the “next normal”

The rapid escalation of COVID-19 around the world was a reckoning and a wake-up call for manufacturers large and small, exposing flaws and inefficiencies many didn’t know they had. According to the Deloitte report COVID-19: Managing supply chain risk and disruption, the manufacturers best positioned to succeed in the environment that lies ahead will have:

“[B]uilt strong relationships with key suppliers and have put systems in place to provide visibility across the extended supply network to better understand their risks and drive specific actions based on their priorities.

They developed agility within their production and distribution networks to quickly reconfigure and maintain supply to global demand, and they invested in supply chain planning and control tower solutions to better sense and respond, and even predict, supply chain issues.”

IBM Product Master checks each of these boxes with a single solution, delivering breakthrough performance for your manufacturing supply chain in the areas of visibility, data quality, agility, robustness, and responsiveness.

To find out how IBM Product Master can help your organization adapt to whatever lies ahead, watch here our latest webinar now!

Find more content about

IBM InfoSphere (3) IBM Product Master (5) Master Data Management (3) Manufacturing Supply Chain (1)